AI FEMS

AI Factory Energy Management

To prevent global warming, we need to reduce energy consumption or use energy efficiently.

Energy is consumed in homes, commercial buildings, and industries, and among them, industrial energy consumption

accounts for the largest proportion, accounting for 60% of Korea and 40% of the world (World Energy Outlook

2021), so it is an important issue to efficiently use industrial consumption such as factories.

We are building energy consumption efficiency through control automation and interconnection with power

facilities to increase the utilization of FEMS for manufacturing plants that need energy rationalization using

artificial intelligence for rational energy management in the industrial sector.

- Maintaining efficient power supply with AI for power quality in manufacturing facilities

- Analyze real-time energy usage and production data using AI and RPA (Robotic Process Automation) in FEMS-enabled production facilities

- Suggest optimal settings that can be applied immediately through AI and RPA, providing efficiency and convenience by immediately identifying actual improvement results

System Structure

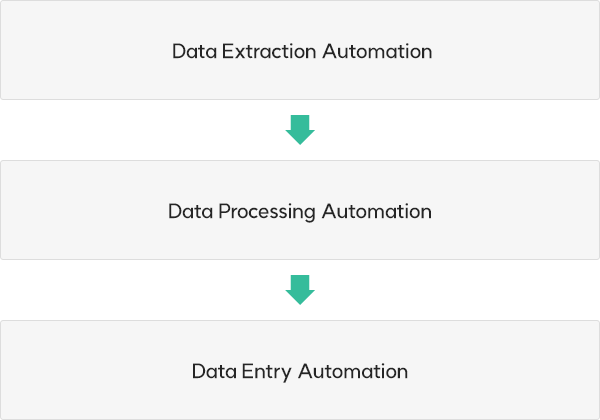

FEMS data pre-processing and standardization automation system based on Robotic Process Automation (RPA)

- Collect and transform unstructured data into intelligent data using AI and RPA

- Data preparation for AI analysis or pre-processing and standardization of collected data

Repetitive tasks of collecting and refining (pre-processing/standardizing) data collected in real-time from FEMS are performed by defined processes (algorithms) and sent to AI specialized data analysis tools.

RPA-based IoT Sensor and Equipment/Facility Anomaly Monitoring

- Supports proactive risk management by identifying failures and abnormal signals after processing structured data produced by FEMS facilities/equipment and IoT sensors

- Real-time DB collection, real-time monitoring, equipment failure detection, abnormal signal detection

- Recognize unstructured data such as videos, texts, and images of energy efficiency-related equipment of equipment/facilities, process and pre-process them in real time for 24 hours, and quickly and accurately deliver and share them to AI analysis systems.

RRPA-based Energy Efficiency Algorithms Test

- Reduce project time, effort, and cost by automating pre-testing and follow-up tasks based on AI predictions (algorithms).

- Test for OS, Mobile Device, Other embeded devices

- Test for automatic facilities, controllers (sensors, PLCs), instruments, utilities and interconnected facilities (boilers, industrial furnaces, air conditioning, compressors, etc.)

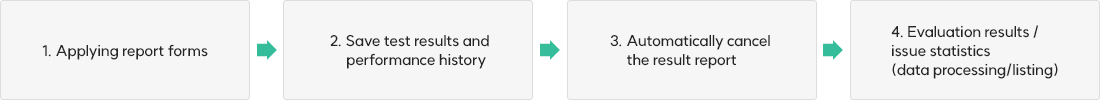

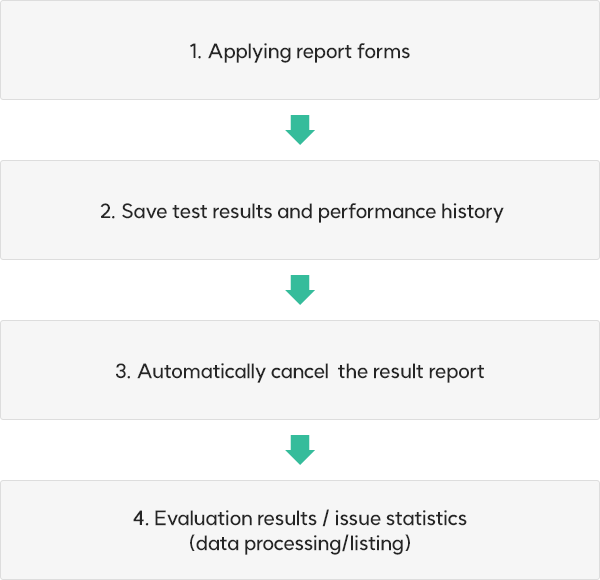

Process

1. Preparation

- Create an automation project (develop scripts and establish resources)

- Modifying and updating scripts

2. Evaluation Control, Management

- System Registration/Administration (Remote Site Verification Automation System)

- Automation project transfer

- Execution Control (Test Start, Pause, Stop)

3. Automation evaluation/performance monitoring

- Check the status of the system (detect failures in the verification system and targets)

- Display test information of the system (progress, pass/fail status)

4. Collecting Results